- Details

- Hits: 11633

Truss Rod repair

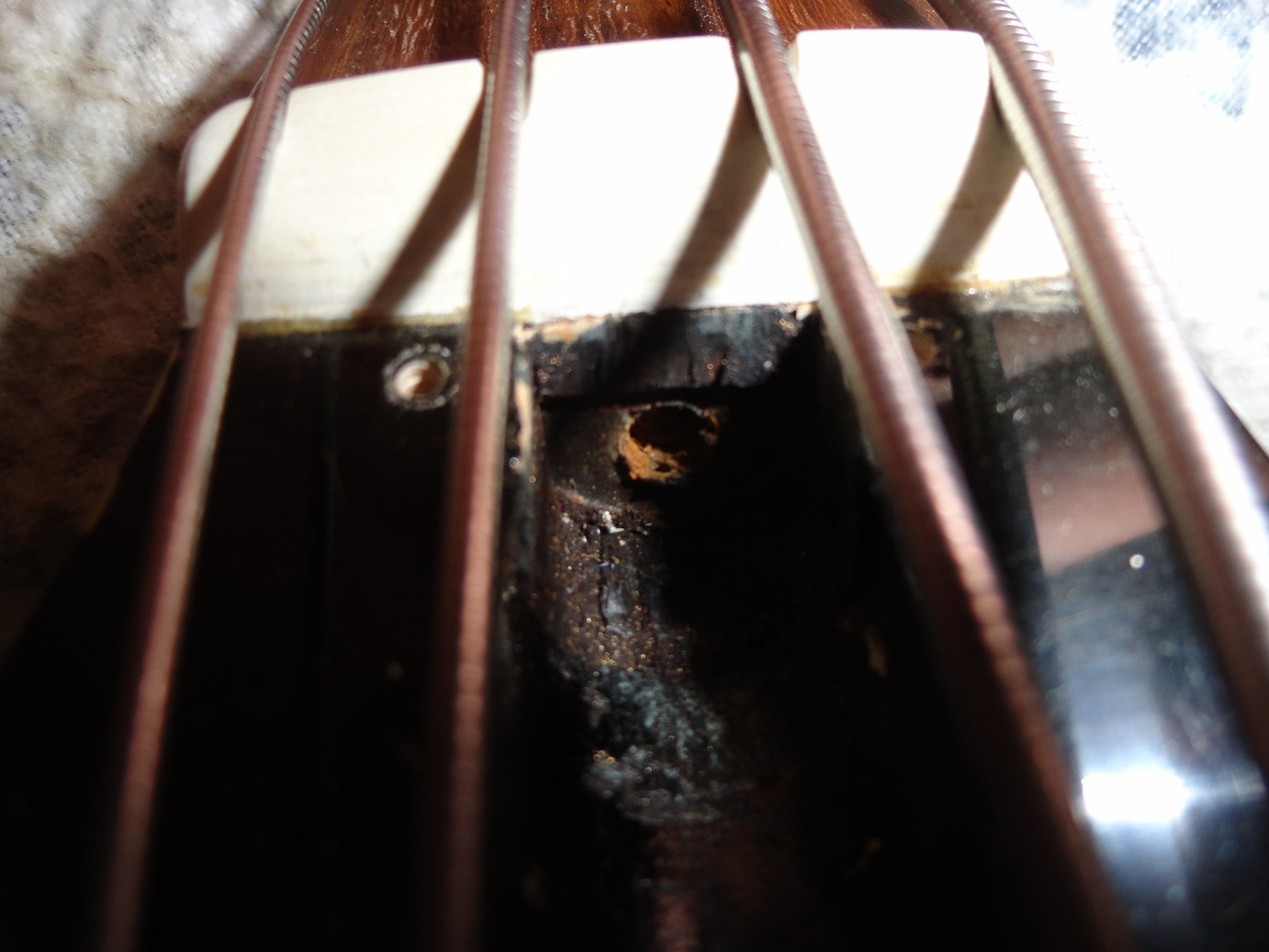

Broken truss rod on a 1969 Gibson EBO-L

Well, this is not a common instrument, and it was handed to me with a very uncommon problem. The Gibson EBO's had all the caracteristics of a good instrument, except one: The bridge assembly. The bridges on EBO's would flex over the years, this  generated improper radiuses, intonation problems, action problems and buzzing problem, pretty much everything you want to avoid on an instrument. When you couple these problems with the common misconception that an instrument's action can be adjusted by the truss rod, bad things can happen. So, for the record, the truss rod must NEVER be used to adjust the action. Adjustin the flex in the neck of an instrument will, inevitably, have an impact on the action, but that's not what the truss rod is for. The truss rod must only me used to adjust the relief in the neck, nothing else.

generated improper radiuses, intonation problems, action problems and buzzing problem, pretty much everything you want to avoid on an instrument. When you couple these problems with the common misconception that an instrument's action can be adjusted by the truss rod, bad things can happen. So, for the record, the truss rod must NEVER be used to adjust the action. Adjustin the flex in the neck of an instrument will, inevitably, have an impact on the action, but that's not what the truss rod is for. The truss rod must only me used to adjust the relief in the neck, nothing else.

Now, the owner of this bass had all the aforementioned problems with the bridge, and he decided to lower the action by tightening the truss rod. He tigntened and tightened until, all of a sudden, SNAP! The hex nut and the truss rod broke clean off, as you can see in the picture. This type of break is rare, but this is a 1969 Gibson, and fixing it is worth the expense.

In order to make this truss rod functional again, I have to free up space in the neck, under the fingerboard, thread the newly found rod material, install a stopper, or spacer, grease the threads and install a new Hex nut. All this has to be done without damaging the finish. So, this is not the easiest of jobs. But I did it. All went well. It took about 2 hours to clean up the maple around the rod. I had to be very careful because, if I accidently nicked the rod, where would the new threads go?

In order to make this truss rod functional again, I have to free up space in the neck, under the fingerboard, thread the newly found rod material, install a stopper, or spacer, grease the threads and install a new Hex nut. All this has to be done without damaging the finish. So, this is not the easiest of jobs. But I did it. All went well. It took about 2 hours to clean up the maple around the rod. I had to be very careful because, if I accidently nicked the rod, where would the new threads go?